Precision CNC Machining Service at ATT Machine: Your Complete OEM Solution

Finding a reliable partner for custom manufacturing can be challenging. You need more than just a shop that cuts metal; you need a comprehensive solution provider. If you are searching for a high-precision CNC machining service that handles everything from raw material to finished product, you have come to the right place.

As a dedicated Original Equipment Manufacturer (OEM), ATT MACHINE streamlines your supply chain by integrating advanced technologies like laser cutting, laser welding, and powder coating under one roof. This article explores how our all-in-one manufacturing capabilities can reduce your costs and accelerate your time-to-market.

What is a Comprehensive CNC Machining Service?

CNC Machining Service is a subtractive manufacturing process that uses computer-controlled machine tools to create custom-designed parts from a workpiece. A comprehensive service goes beyond simple cutting; it encompasses the entire production lifecycle, including milling, turning, fabrication, assembly, and surface finishing to meet strict engineering tolerances.

Why Partner with an Original Equipment Manufacturer (OEM)?

When outsourcing production, working directly with an Original Equipment Manufacturer is crucial for quality control and cost efficiency. Unlike trading companies, an OEM partner offers:

-

Direct Communication: Talk directly to the engineers handling your project.

-

Cost Savings: Eliminate middleman markups.

-

Design for Manufacturing (DFM): We optimize your CAD designs to ensure they are feasible and cost-effective to produce.

-

Scalability: Whether you need a single prototype or 10,000 units, we scale with your business.

Our Integrated Capabilities: Beyond Standard Machining

We stand out by offering a "One-Stop Shop" ecosystem. Here is how we combine technologies to deliver superior parts:

1. Precision CNC Milling & Turning

Our core competency lies in multi-axis CNC machining. We utilize state-of-the-art 3, 4, and 5-axis machines to produce complex geometries with tolerances as tight as ±0.005mm. This is ideal for automotive, medical, and aerospace components.

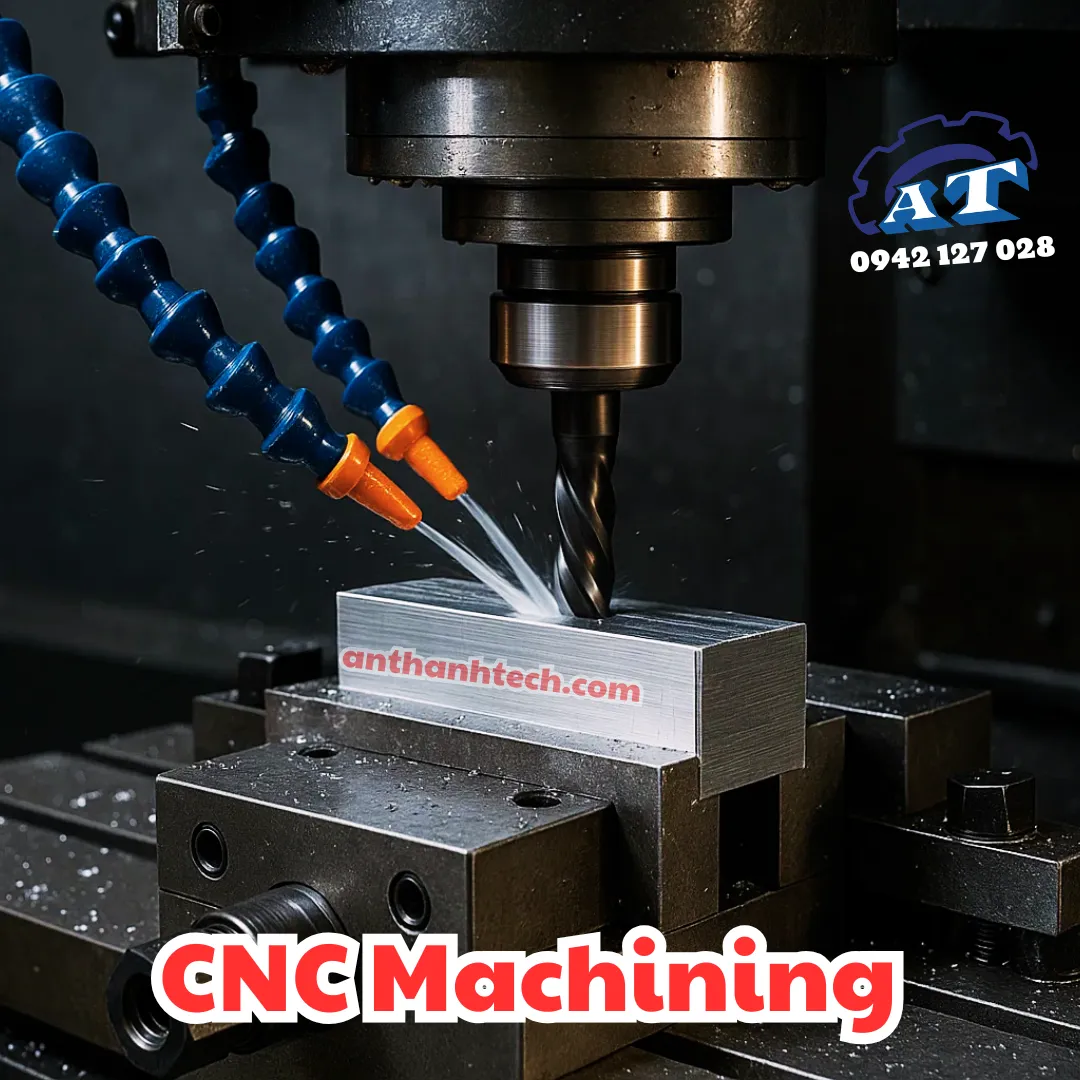

Precision CNC machining service at ATT MACHINE.

2. High-Speed Laser Cutting

Before machining or assembly, sheet metal often requires precise profiling. Our laser cutting service handles materials like stainless steel, aluminum, and carbon steel with exceptional speed and clean edges, minimizing material waste.

High speed laser cutting service for sheet metal.

3. Advanced Laser Welding

For assembly needs, we utilize laser welding technology. Compared to traditional TIG/MIG welding, laser welding offers:

-

Minimal Thermal Distortion: Keeps the part's geometry intact.

-

Deep Penetration: Ensures strong, durable joints.

-

Aesthetic Finish: Reduces the need for post-weld grinding.

Advanced laser welding for precise metal assembly.

4. Durable Powder Coating

A raw metal part is not finished until it is protected. Our in-house powder coating line provides a superior finish that is tougher than conventional paint. It protects your parts against corrosion, chemicals, and weather, making it perfect for industrial and outdoor applications.

Durable powder coating service for industrial parts.

5. Precision Sheet Metal Bending

To transform flat laser-cut parts into complex 3D structures, bending is an essential step. At attmachine.com, we utilize advanced CNC hydraulic press brakes that ensure extreme angle accuracy and repeatability.

-

Complex Geometries: From simple 90-degree bends to multi-bend complex brackets.

-

Versatility: Capable of bending various materials, including stainless steel, aluminum, and heavy-duty carbon steel.

-

Precision: Automated crowning systems to ensure the bend angle is consistent across the entire length of the part.

Precision CNC sheet metal bending service at ATT MACHINE

Material Selection Guide

We work with a wide range of materials to suit your specific application requirements:

| Material Category | Common Grades | Typical Applications |

| Aluminum | 6061, 7075, 5052 | Aerospace parts, enclosures, brackets |

| Stainless Steel | 303, 304, 316L | Medical devices, food processing equipment |

| Steel | Mild Steel, Tool Steel | Heavy machinery, structural components |

| Plastics | POM (Delrin), PEEK, Nylon | Gears, bushings, insulators |

| Brass/Copper | C36000, C11000 | Electrical contacts, fittings |

| Aluminum | 5052, 6061 | Enclosures, Chassis, Brackets |

| Stainless Steel | 304, 316L | Food-grade containers, Medical housings |

| Carbon Steel | Q235, A36 | Structural frames, Heavy duty parts |

Our 5 Step Production Process

We follow a rigorous workflow to ensure every part meets your specifications:

-

Quote & DFM Analysis: Submit your CAD files (STEP/IGES) to ATT MACHINE. Our engineers review them for manufacturability within 24 hours.

-

Prototyping: We create a sample to verify design and functionality.

-

Production: Utilizing CNC machining, laser cutting, or laser welding based on the project plan.

-

Surface Finishing: Applying powder coating or anodizing for the final touch.

-

Quality Control (QC) & Global Shipping: 100% inspection using CMM before secure delivery worldwide.

Frequently Asked Questions (FAQ)

Q: Do you provide design services for OEM projects?

A: Yes, as an Original Equipment Manufacturer at ATT MACHINE, we can assist with 3D modeling and Design for Manufacturing (DFM) to optimize your parts for production.

Q: What is the advantage of laser welding over TIG welding?

A: Laser welding is faster, more precise, and inputs less heat into the material, resulting in less deformation and a cleaner look.

Q: Can you handle both CNC machining and powder coating for one order?

A: Absolutely. We offer end-to-end services. We machine the parts and immediately move them to our powder coating line, saving you time and logistics costs.

Q: What is the maximum thickness you can handle for bending?

A: Our CNC press brakes can handle various thicknesses depending on the material length, typically up to 12mm for mid-range lengths. Please contact our technical team at attmachine.com with your specific drawing for a detailed capability check.

Conclusion

Choosing the right manufacturing partner is critical for your product's success. With our expertise in CNC machining service, combined with laser cutting, laser welding, and powder coating, ATT MACHINE delivers high-quality, ready-to-use parts to clients worldwide.

Ready to start your project?

Contact ATT MACHINE today to upload your drawings and get a competitive quote within 24 hours. Let us bring your designs to life with precision and efficiency.