At An Thanh Tech in Ho Chi Minh City, Vietnam, our laser cutting service specializes in laser cut steel sheet projects, combining powerful fiber lasers with CNC machining for complete, high-tolerance finished parts. With over 16 years of expertise, ISO 9001:2015 & ISO 14001:2015 certifications, and a proven track record serving global clients like Samsung, Bosch, and VinGroup, we handle everything from thin-gauge sheets to thicker plates up to 25mm.

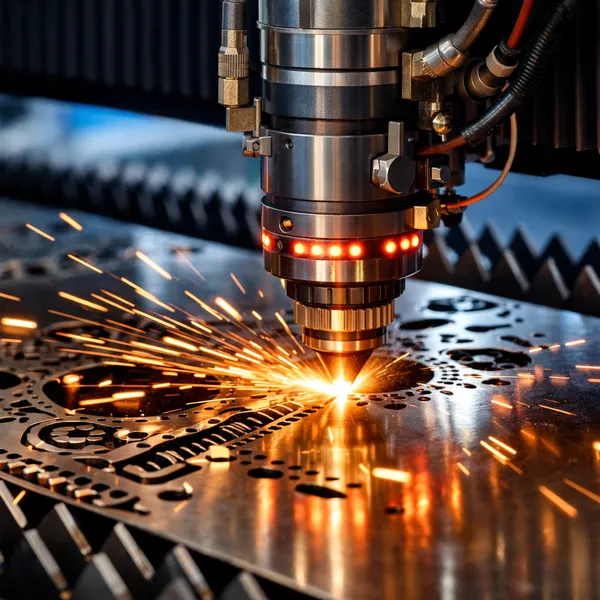

Fiber laser cutting machine in operation with bright sparks, precisely laser cutting a steel sheet in a professional industrial setting for clean, high-speed results.

Advantages of Laser Cutting for Steel Sheets

Fiber laser cutting outperforms traditional methods (plasma, waterjet, or mechanical shearing) when processing steel sheets:

- Precision: Tolerances as tight as ±0.05–0.1mm (up to ±0.01mm on critical features)

- Edge Quality: Smooth, dross-free cuts with minimal heat-affected zone

- Speed: Extremely fast on mild steel, carbon steel, and stainless steel

- Material Range: Handles reflective stainless steel and thick carbon steel effectively

- Cost Efficiency: Reduced secondary finishing and optimized nesting to minimize scrap

For parts needing drilled holes, threads, milled pockets, or precise countersinks, we integrate CNC machining directly after laser cutting—ensuring one-stop production without quality loss.

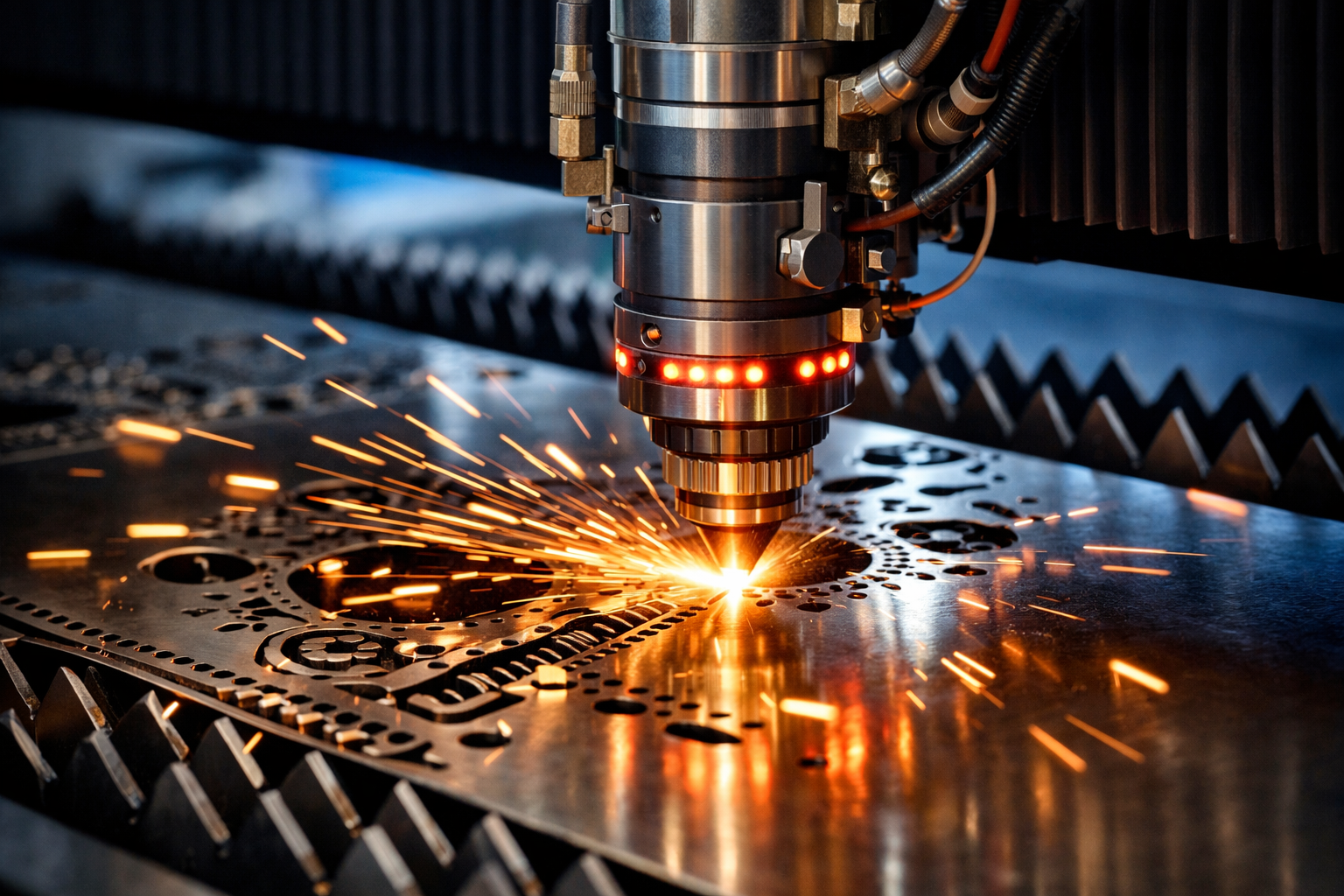

Close-up of industrial laser cutting steel sheet with flying sparks and precise beam focus, demonstrating advanced laser cutting capabilities on metal.

Steel Types and Thickness Capabilities for Laser Cut Sheet

| Steel Type | Typical Thickness Range | Common Applications | Laser Cutting + CNC Notes |

|---|---|---|---|

| Mild / Carbon Steel | 0.5–25 mm | Machinery frames, brackets, structural | High-speed cuts; excellent for heavy CNC |

| Stainless Steel (304/316) | 0.5–20 mm | Enclosures, medical, food processing | Clean, oxide-free edges; ideal for tapping |

| Galvanized Steel | 0.5–12 mm | Construction, HVAC, automotive | Good corrosion resistance post-cut |

| Tool Steel / AR400 | 3–15 mm (inquire) | Wear-resistant parts, armor | Specialized settings for hardness |

We optimize parameters (power, gas, speed) for each steel grade to achieve the best edge quality.

Precision laser cut stainless steel sheet samples with intricate patterns, smooth edges, and complex shapes ready for further processing.

Full Process: From Laser Cut Steel Sheet to Finished Part

- Laser Cutting — Creates accurate 2D profiles from steel sheets.

- CNC Machining — Adds 3D features:

- Precision drilling and tapping

- Milling slots, pockets, or contours

- Chamfering and deburring

- Additional Services — CNC bending, laser welding, powder coating.

- Quality Control — 100% inspection with CMM and visual checks.

This integrated workflow minimizes lead times and ensures consistency.

CNC-machined steel part from laser-cut sheet featuring drilled holes, threads, and milled features, showing high-precision laser cutting service results.

High-precision CNC machining center drilling and milling a laser-cut steel sheet component in a modern fabrication workshop.

Sheet Metal Laser Cutting: Fundaments for Laser Cutting Metal

Ordering Your Laser Cut Steel Sheet Project

- Upload files (.DXF, .DWG, .STEP, .IGES; PDFs/sketches welcome – free conversion).

- Get free DFM review: Suggestions to optimize design, cost, and manufacturability.

- Production & QC: Laser cutting → CNC machining → finishing.

- Delivery: Local HCMC pickup or global shipping (3–7 days air/express).

Frequently Asked Questions

What steel thicknesses can you laser cut accurately?

From 0.5 mm thin sheets to 25 mm thick carbon steel; stainless up to 20 mm with excellent results.

How does laser cutting compare to other methods for steel sheet?

Laser offers superior speed, precision, and edge quality over plasma (for thinner materials) or waterjet (slower and more expensive).

Can you add CNC machining features after laser cutting steel?

Yes – drilling, tapping, milling, and more are standard in our one-stop laser cutting service.

Ready for your laser cut steel sheet project? Contact us for an instant quote.

Address: 32-34 Duong D. Cong Khi, Ap 1, Hoc Mon, Ho Chi Minh City, Vietnam

Hotline: +84 942 127 028 (24/7)

More info: Laser Cutting Service

Send your drawings today – precision starts here!

Xem thêm