At An Thanh Tech in Ho Chi Minh City, Vietnam, we provide professional laser cutting service specializing in cutting sheet metal using advanced fiber laser technology and full CNC capabilities. With 16+ years of experience, ISO 9001:2015 and ISO 14001:2015 certifications, and a large-scale facility, we serve clients across Vietnam and internationally—including major names like VinGroup, Samsung, and Bosch.

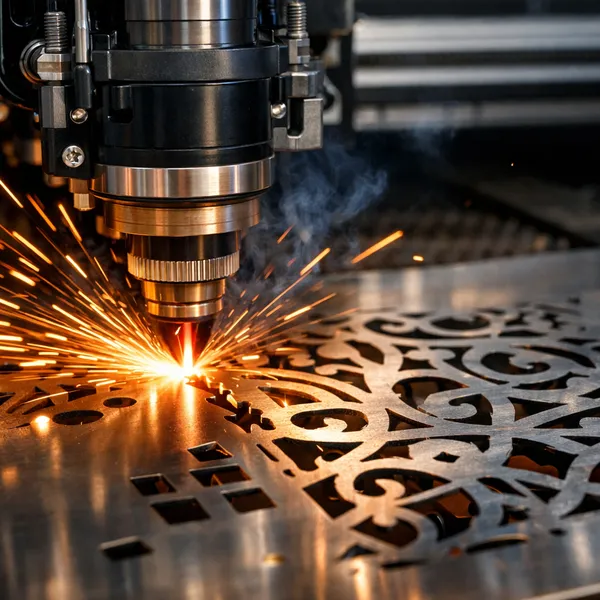

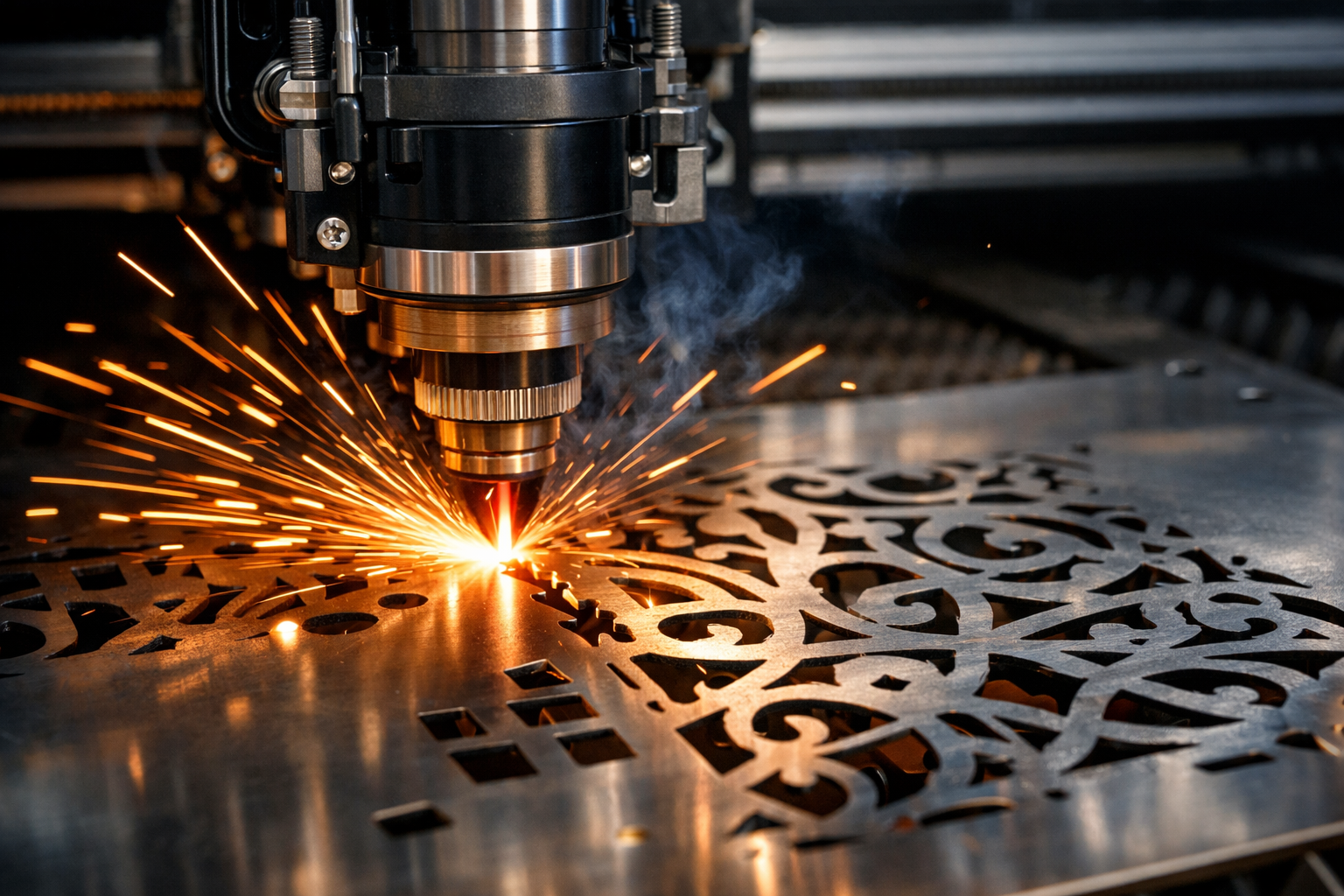

High-power fiber laser cutting machine actively cutting stainless steel sheet metal with precise, clean edges and high speed in a professional Vietnam factory.

Why Laser Cutting Excels for Cutting Sheet Metal

Fiber laser cutting uses a concentrated beam to vaporize or melt material with almost no contact, producing:

- Extremely tight tolerances (±0.05–0.1mm standard; up to ±0.01mm possible)

- Burr-free edges with minimal heat-affected zone

- High cutting speeds (up to meters per second on thin sheets)

- Excellent results on reflective metals like aluminum, stainless steel, and copper

- Sheet sizes up to 3000 × 1500 mm or larger

When cutting sheet metal with laser alone isn't enough (e.g., for threaded holes or milled features), we seamlessly transition to CNC machining for secondary operations.

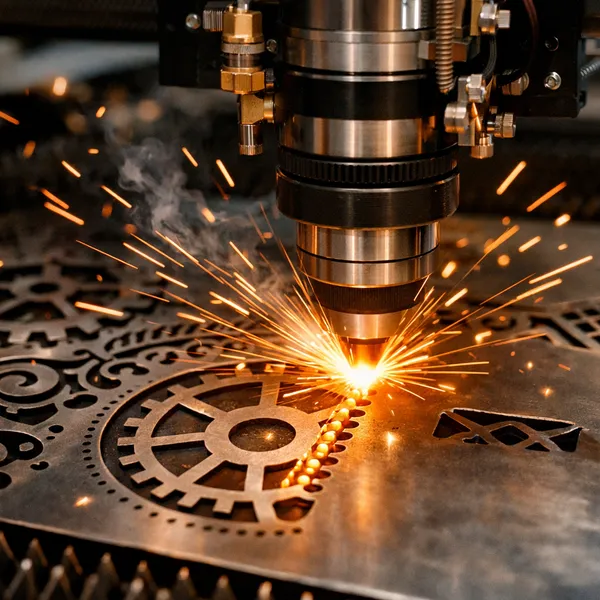

Alt text: Fiber laser in action cutting intricate patterns on sheet metal, demonstrating clean cuts and minimal distortion typical of advanced laser cutting service.

How to Laser Cut Stainless Steel Effectively?

Integrated Laser Cutting + CNC Machining Process

- Laser Cutting — Creates accurate flat profiles from sheet metal.

- CNC Machining — Adds precision features:

- Drilling and tapping for threads

- Milling pockets, slots, or contours

- Countersinking, chamfering, and deburring

- Tight positional accuracy for assemblies

This hybrid approach is ideal for cutting sheet metal parts that require both speed (from laser) and complexity (from CNC).

CNC machining center performing drilling and milling on a laser-cut sheet metal component, highlighting integrated laser cutting and CNC machining workflow.

Materials We Specialize in for Cutting Sheet Metal

| Material | Thickness Range | Best Applications | Laser + CNC Benefits |

|---|---|---|---|

| Stainless Steel | 0.5–20 mm | Enclosures, medical, food equipment | Clean edges, easy tapping and milling |

| Aluminum | 0.5–15 mm | Electronics, aerospace panels | Fast cuts, precise lightweight features |

| Carbon Steel | 0.5–25 mm | Structural frames, machinery bases | High-speed thick cuts + heavy machining |

| Brass / Copper | 0.5–10 mm | Electrical components, decorative panels | Minimal oxidation, fine detailing |

| Galvanized / Mild Steel | 0.5–12 mm | Construction, automotive brackets | Cost-effective with good thread holding |

Precision laser-cut and CNC-machined sheet metal enclosure featuring drilled holes, threads, and smooth finishes, showcasing complete laser cutting service results.

Additional Capabilities in Our Sheet Metal Service

- Precision Bending: CNC press brakes for accurate angles after cutting.

- Laser Welding: Strong, low-distortion joins.

- Finishing: Powder coating, deburring, and surface treatment.

- Quality Assurance: 100% inspection with CMM, material certificates available.

Sheet metal parts after laser cutting showing clean, deburred edges and ready for further CNC machining or bending.

Simple Ordering Process for Cutting Sheet Metal Projects

- Upload drawings (.DXF, .DWG, .STEP, .IGES; PDFs/sketches accepted – free conversion).

- Receive free DFM feedback: Design optimization for cost and manufacturability.

- Production: Laser cutting → CNC machining → finishing → full QC.

- Delivery: Fast local pickup in HCMC or global shipping (3–7 days air/express).

Frequently Asked Questions

What's the best way to cut sheet metal accurately and quickly? Fiber laser cutting is the fastest and most precise for 2D profiles; pair it with CNC machining for any 3D features needed.

Can you achieve very tight tolerances when cutting sheet metal?

Yes – typically ±0.05–0.1 mm overall; we confirm specifics during DFM review.

Do you handle both small prototypes and large orders?

Absolutely – from single custom parts to high-volume production.

Ready to start your cutting sheet metal project with professional laser cutting service and CNC machining?

Get in touch for an instant quote.

Address: 32-34 Duong D. Cong Khi, Ap 1, Hoc Mon, Ho Chi Minh City, Vietnam

Hotline: +84 942 127 028 (24/7)

More details: Laser Cutting Service

Upload your drawings today – let's build it precisely!

Xem thêm