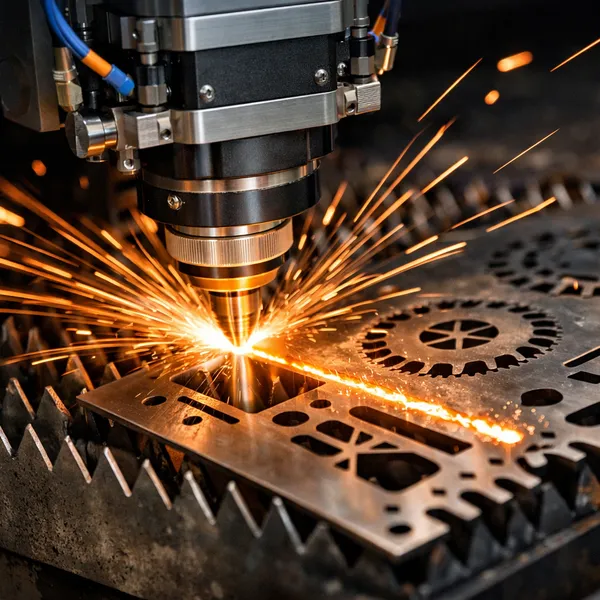

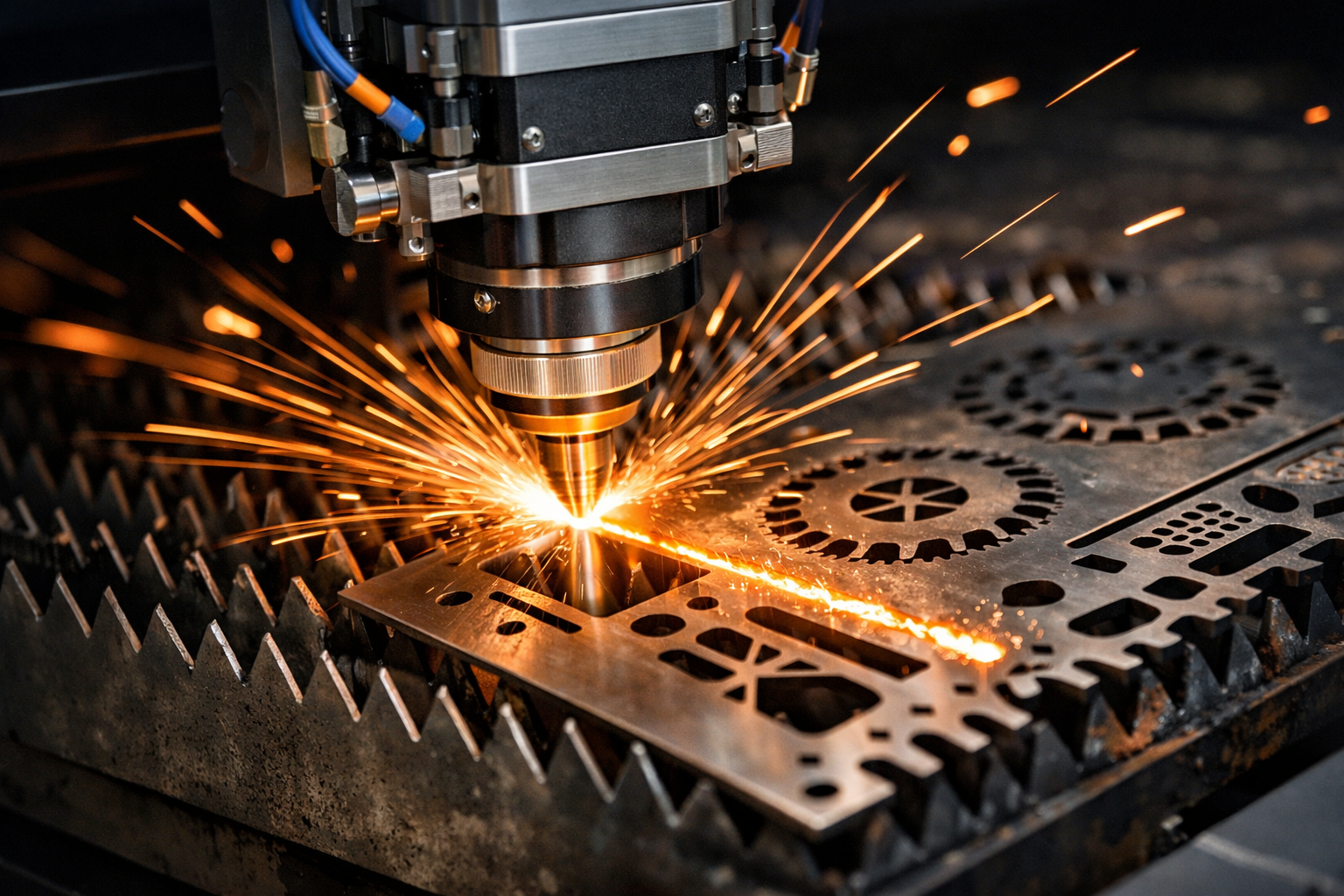

Cutting sheet metal is a high-precision fabrication process using CNC laser cutting to produce accurate, clean-edged components from flat metal sheets (stainless steel, mild steel, aluminum, copper, brass, titanium). At ATT Machine, we offer world-class cutting sheet metal services for clients in the United States and Europe, delivering tolerances of ±0.01mm, no black edges, and production in 24-48 hours, with prices 20-25% lower than domestic US/EU rates. All parts are RoHS, REACH, ASTM, and EN compliant, with full export documentation and fast global shipping (7-14 days door-to-door via DHL/FedEx).

1. Why Cutting Sheet Metal with Laser is the Preferred Choice for US & European Manufacturers in 2026

In 2026, the global sheet metal fabrication market is expected to reach $450 billion (Statista & Grand View Research), driven by:

- Electric Vehicle (EV) production – Tesla, Rivian (US), Volkswagen, BMW (Europe) require lightweight aluminum and high-strength steel parts

- Medical & pharmaceutical equipment – FDA & EU MDR demand ultra-clean stainless steel components

- Aerospace & defense – Boeing, Airbus, Lockheed Martin need zero-distortion titanium & aluminum

- Renewable energy – Solar panel frames, wind turbine components require corrosion-resistant stainless steel

Laser cutting sheet metal outperforms traditional punching, waterjet, and plasma cutting in:

- Precision (±0.01mm vs. ±0.1mm)

- Speed (up to 5x faster)

- Material savings (kerf width 0.1-0.3mm)

- No tooling costs

- Sustainability (70% less energy than CO2 lasers)

ATT Machine specializes in exporting precision-cut sheet metal parts to California, Texas, New York, London, Berlin, Paris, Amsterdam, and Milan – with full traceability and compliance.

2. Materials & Thickness Capabilities – Cutting Sheet Metal at ATT Machine

| Material | Max Thickness | Tolerance | Edge Quality | Typical US/EU Applications |

|---|---|---|---|---|

| Stainless Steel 304/316 | 30mm | ±0.01mm | Mirror, no burr | Medical devices, food processing, architecture |

| Mild Steel (Carbon Steel) | 40mm | ±0.015mm | Clean, minimal HAZ | Automotive chassis, machinery frames |

| Aluminum (6061/5083) | 40mm | ±0.01mm | Burr-free | EV battery trays, aerospace panels |

| Brass & Copper | 12-15mm | ±0.015mm | High precision | Electrical enclosures, heat exchangers |

| Titanium (Grade 2/5) | 10mm | ±0.01mm | Burr-free | Aerospace brackets, medical implants |

Key Advantage for International Clients

- Full compliance with RoHS, REACH, ASTM A240, EN 10088

- 100% inspection using Zeiss 3D CMM

- Export documentation (CO/CQ, material certificates) included

3. Why US & European Companies Choose ATT Machine for Cutting Sheet Metal

- No Minimum Order Quantity (MOQ) – Perfect for prototypes (1 piece) or high-volume production

- End-to-End Service – Laser cutting + CNC bending + TIG welding + Mirror 8K polishing

- Proven Export Experience – Delivered 6,000+ precision parts to US & Europe in 2025

- English & German Support – Dedicated international team

- IP Protection – NDA signed for every project

- Cost Savings – 20-25% lower than domestic rates in California, Texas, Germany, UK

4. Transparent Pricing for International Clients

| Material & Thickness | Price (USD/inch or EUR/cm) | Remark (US/EU Compliance) |

|---|---|---|

| Stainless Steel 304/316 (1-10mm) | $0.12 – 0.26/inch | Mirror edge, RoHS compliant |

| Stainless Steel 316 (11-30mm) | $0.42 – 0.96/inch | 15kW fiber laser, REACH compliant |

| Mild Steel (1-40mm) | $0.10 – 0.24/inch | ASTM A36/A240 certified |

| Aluminum (1-40mm) | $0.16 – 0.38/inch | No burr, EN AW standards |

| Mirror 8K Polishing Add-On | $12.40 – 26/inch² | True mirror finish (REACH compliant) |

Discounts for US & EU

- 15–45% off for orders over 200 meters / 500 pieces

- Free 3D design review + free DFM (Design for Manufacturing) feedback

5. Top 10 Most Requested Cutting Sheet Metal Projects from US & Europe

- Stainless steel medical device enclosures

- Aluminum EV battery tray components

- Aerospace brackets & panels (titanium & aluminum)

- Food-grade stainless steel processing equipment

- Architectural metal signage & logos

- Automotive prototype sheet metal parts

- Industrial machine guards & covers

- Precision sheet metal enclosures for electronics

- Decorative metal panels & sculptures

- High-end furniture & fixture frames

6. 9 Step Professional Cutting Sheet Metal Process at ATT Machine

- Send your drawing (CAD/DXF/STEP/PDF) or concept

- Receive detailed quote + lead time in 15–30 minutes

- Free 3D design & DFM optimization (if needed)

- Prototype production in 24–48 hours

- Sample approval (photo/video + measurement report)

- Full-scale production with real-time updates

- 100% inspection using Zeiss 3D CMM

- Export-compliant packaging + labeling

- Global shipping (DHL/FedEx) + 3–5 year warranty

7. Frequently Asked Questions – Cutting Sheet Metal for US & Europe

What materials can you cut for US and European clients?

Stainless steel (304/316), mild steel, aluminum, brass, copper, titanium – up to 40mm thick.

Do your parts meet US & EU regulatory standards?

Yes – RoHS, REACH, ASTM A240, EN 10088, full CO/CQ provided.

What is the minimum order quantity?

No MOQ – we produce from 1 prototype to high-volume runs.

How long does shipping take to the US/Europe?

7-14 days door-to-door via DHL/FedEx, full tracking included.

How much can I save compared to domestic US/EU rates?

Typically 20-25% lower, with equal or better quality.

Contact Us Now – Instant Quote for US & European Clients

Hotline / WhatsApp / Zalo 24/7: +84 942 127 028

Email: cokhi.anthanhtech@gmail.com

Website: https://attmachine.com/laser-cutting-machining

Factory Location: Ho Chi Minh City, Vietnam (Export-Ready)

- Extra 18% discount on first order

- Free Mirror 8K polishing for first 30 m²

- Free DFM review + shipping cost credit for new US/EU clients

Final Note: ATT Machine is the leading export-oriented cutting sheet metal provider for US and European markets – precision ±0.01mm, RoHS/REACH compliant, fast 24-48h production, and prices 20-25% below domestic rates. Contact +84 942 127 028 today for an instant quote!

Xem thêm