The Ultimate Guide to 2 Inch Ratchet Straps Sizes Comparison, Safety Tips & Applications

Introduction & Definition

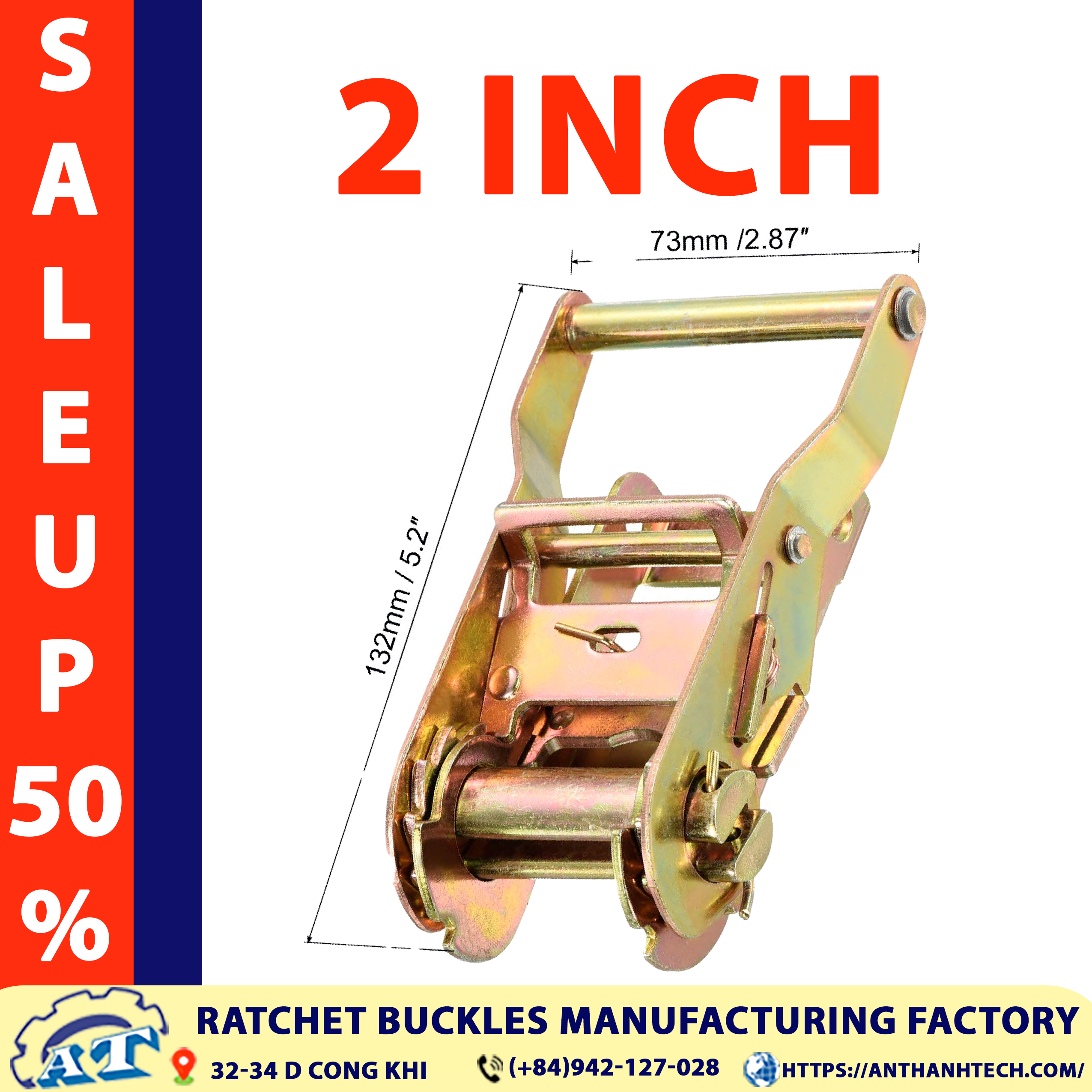

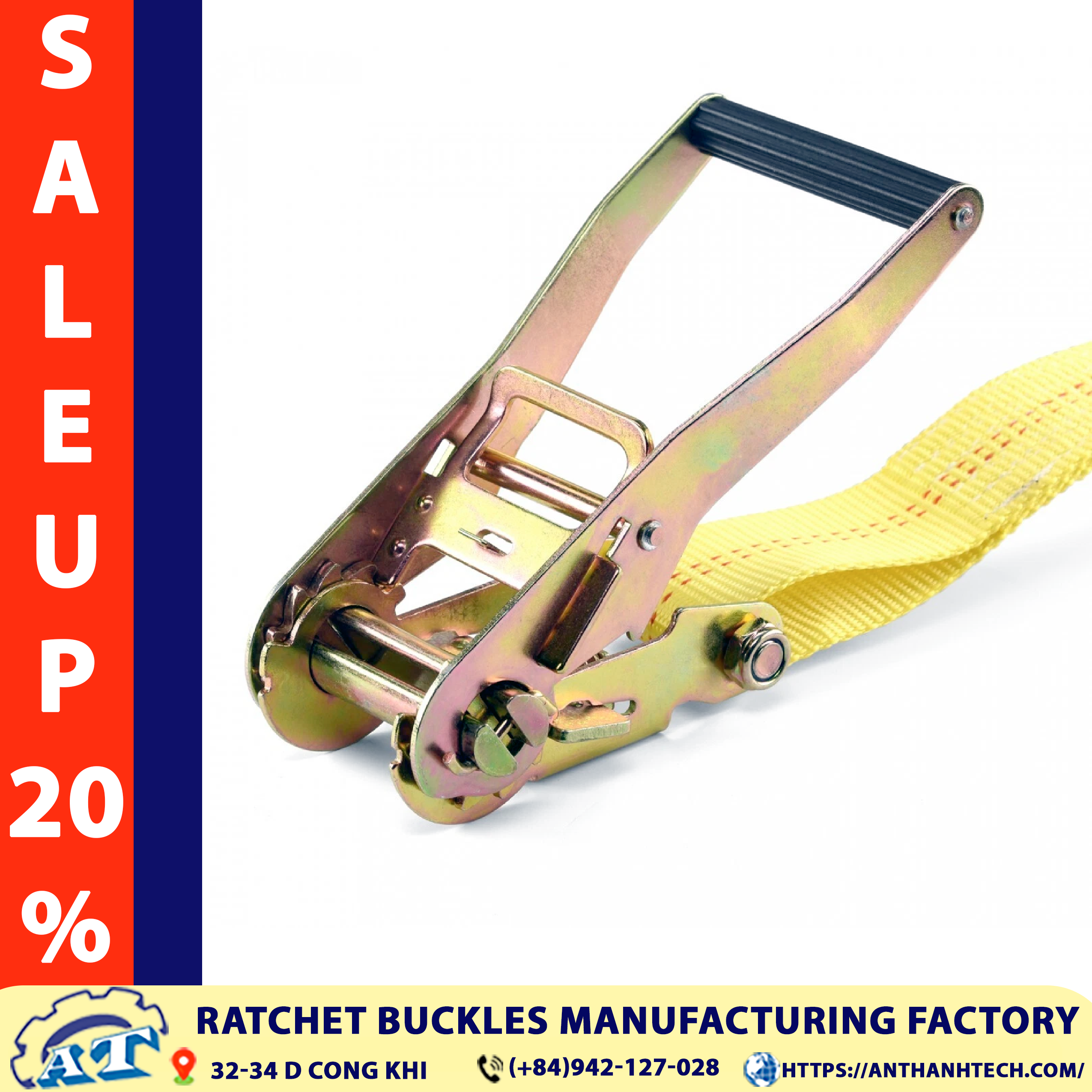

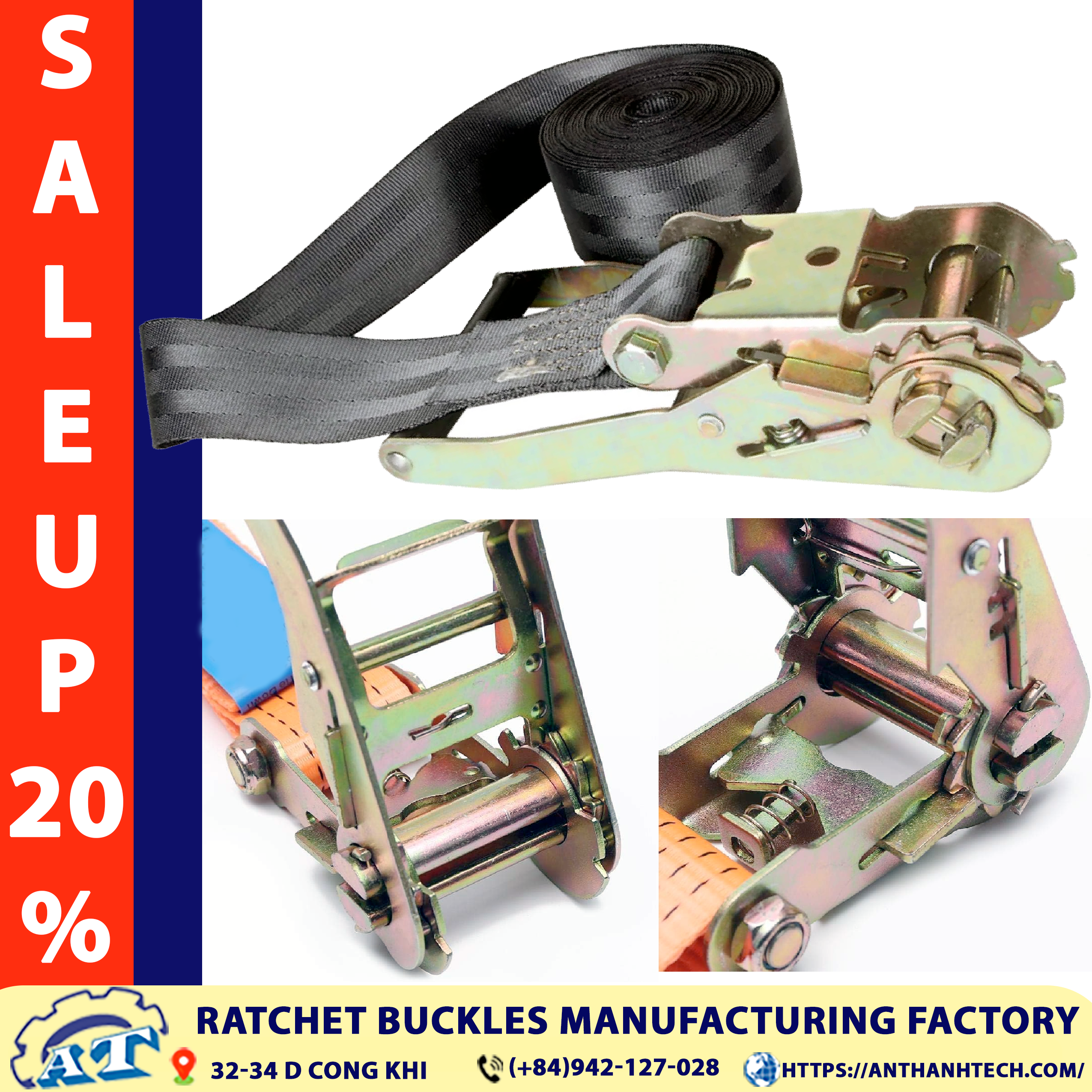

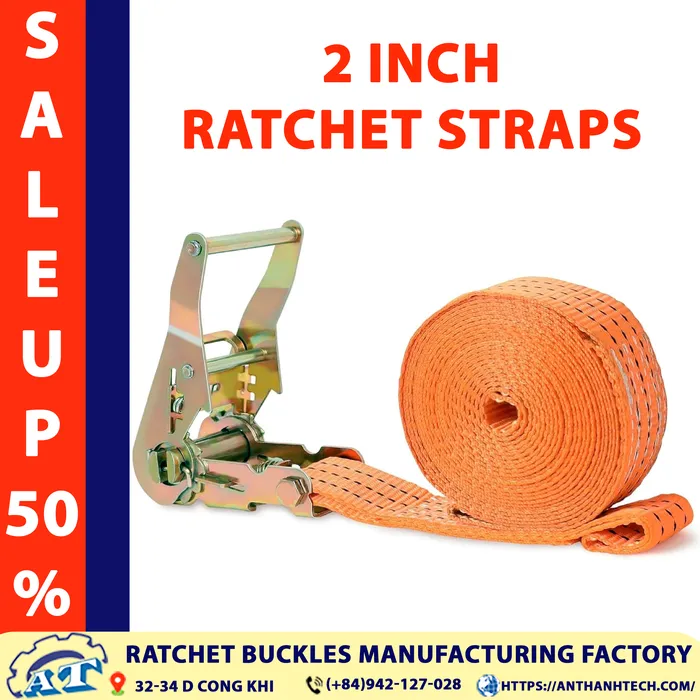

What are 2 Inch Ratchet Straps? 2 inch ratchet straps are the most popular heavy-duty tie-down systems, featuring 50mm polyester webbing and a strong ratchet buckle for high-tension, reliable cargo securing—ideal for professional trucking and serious hauling.

Core Components:

- Polyester Webbing — High-strength, weather-resistant material with minimal stretch.

- Mechanical Ratchet Buckle — Forged steel with extended handle for powerful, precise tightening.

The Advantage: The 2 inch size delivers significantly more strength than smaller options while remaining manageable, far outperforming ropes, cam buckles, or lighter straps in holding power and vibration resistance.

2 Inch Ratchet Tie Down Straps - 5 Ton Capacity | An Thanh

Technical Size Comparison Table

Compare the 2 inch size to others:

| Strap Width | Typical Breaking Strength | Working Load Limit (WLL) | Best Applications/Use Cases |

|---|---|---|---|

| 1 Inch | 1,500–3,000 lbs | 500–1,000 lbs | Light-duty: Motorcycles, small loads |

| 1.5 Inch | 3,000–6,000 lbs | 1,000–2,000 lbs | Medium-duty: ATVs, furniture |

| 2 Inch | 7,000–11,000 lbs | 2,333–3,667 lbs | Heavy-duty: Vehicles, equipment, pallets, flatbed trucking |

| 3 Inch | 15,000–20,000 lbs | 5,000–6,667 lbs | Professional machinery |

| 4 Inch | 20,000–30,000+ lbs | 5,400–10,000 lbs | Extreme industrial loads |

The 2 inch ratchet strap is the industry standard for most commercial and heavy-duty applications.

Expert Selection Guide: The 1/3 Rule

WLL vs. Breaking Strength Breaking strength = max failure load; WLL = safe load (typically 1/3 of breaking).

The 1/3 Rule Cargo weight ÷ WLL per strap = minimum straps required. Example: 10,000 lb load needs at least three 2 inch straps (add redundancy for safety).

End Hardware Options

- J-Hooks — Secure enclosed grip on axles/frames.

- Flat Hooks — Wide contact for E-track/rub rails.

- Wire Hooks — Versatile for chains or slots.

Step-by-Step Safety & Operational Guide

- Inspection — Examine webbing/hardware for damage.

- Threading — Open ratchet; feed webbing through mandrel.

- Tensioning — Pump handle evenly.

- Locking — Close handle; tug test.

- Releasing — Press lever; open flat and pull slowly.

Industrial & Commercial Applications

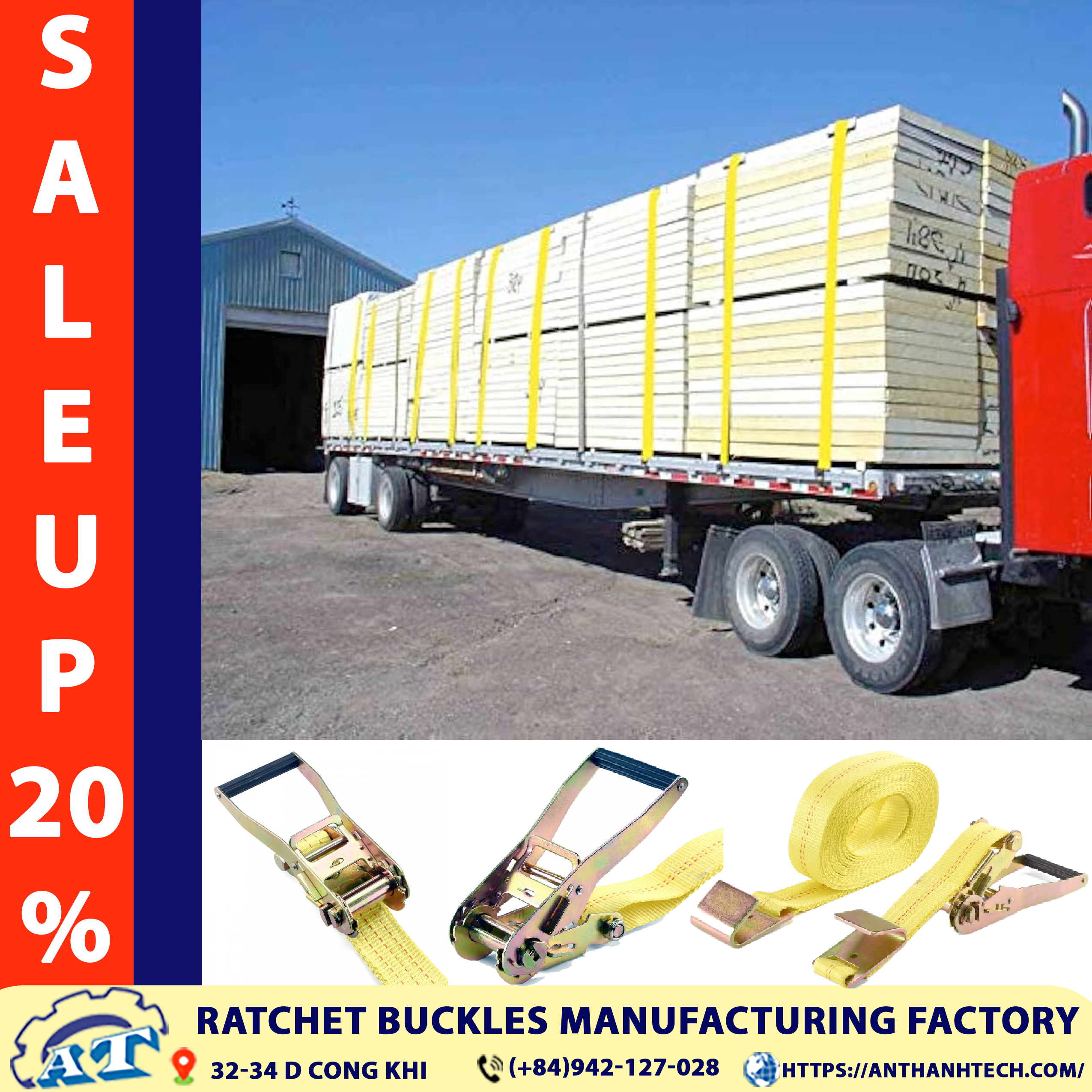

- Logistics/Trucking — Pallets, containers on flatbeds.

- Construction — Lumber, steel, heavy equipment.

- Automotive — Car hauling, vehicle recovery.

- General Hauling — Machinery, boats.

An Thanh Technology Co., Ltd. – Your Manufacturing Partner

An Thanh Technology Co., Ltd. is a leading Asian manufacturer of high-quality 2 inch ratchet straps and cargo securing products, with over 15 years of expertise in Vietnam.

- Compliance — Meets EN 12195-2 and international standards.

- B2B Benefits — OEM/ODM, factory-direct pricing, global shipping (3–7 days).

- Location — 32-34 D. Cong Khi Street, Hamlet 1, Hoc Mon District, Ho Chi Minh City, Vietnam.

Frequently Asked Questions (FAQ)

When should I replace 2 inch ratchet straps? Replace for cuts, frays, UV damage, or rust—every 2–4 years with regular use.

Suitable for extreme weather? Yes—polyester webbing resists moisture, heat, and UV.

J-hook vs. Flat hook? J-hook for secure enclosed grip; flat hook for wide, stable contact on rails.

Contact Information & Call to Action

- Phone/Zalo: (+84) 942.127.028

- Email: cokhi.anthanhtech@gmail.com

- Website: https://anthanhtech.com