High Precision Laser Cutting Service: Fast & Reliable OEM Solutions by ATT MACHINE

In today's fast-paced manufacturing world, precision, speed, and reliability decide who wins contracts. Whether you're prototyping a new product, sourcing custom metal parts, or scaling mass production, choosing the right laser cutting service is crucial.

At ATT MACHINE (An Thanh Tech), a leading precision mechanical engineering company based in Ho Chi Minh City, Vietnam, we deliver world class fiber laser cutting with a full manufacturing ecosystem: CNC machining, precision bending, laser welding, and powder coating. With over 16 years of experience serving 6,500+ businesses—including Samsung, VinGroup, and Bosch—we help international clients get high-quality parts faster and more cost-effectively than many local shops.

Searching for "laser cutting near me"? While local convenience matters, ATT MACHINE offers OEM level quality, tighter tolerances, and global logistics that make us feel "right next door"—with on-time delivery worldwide.

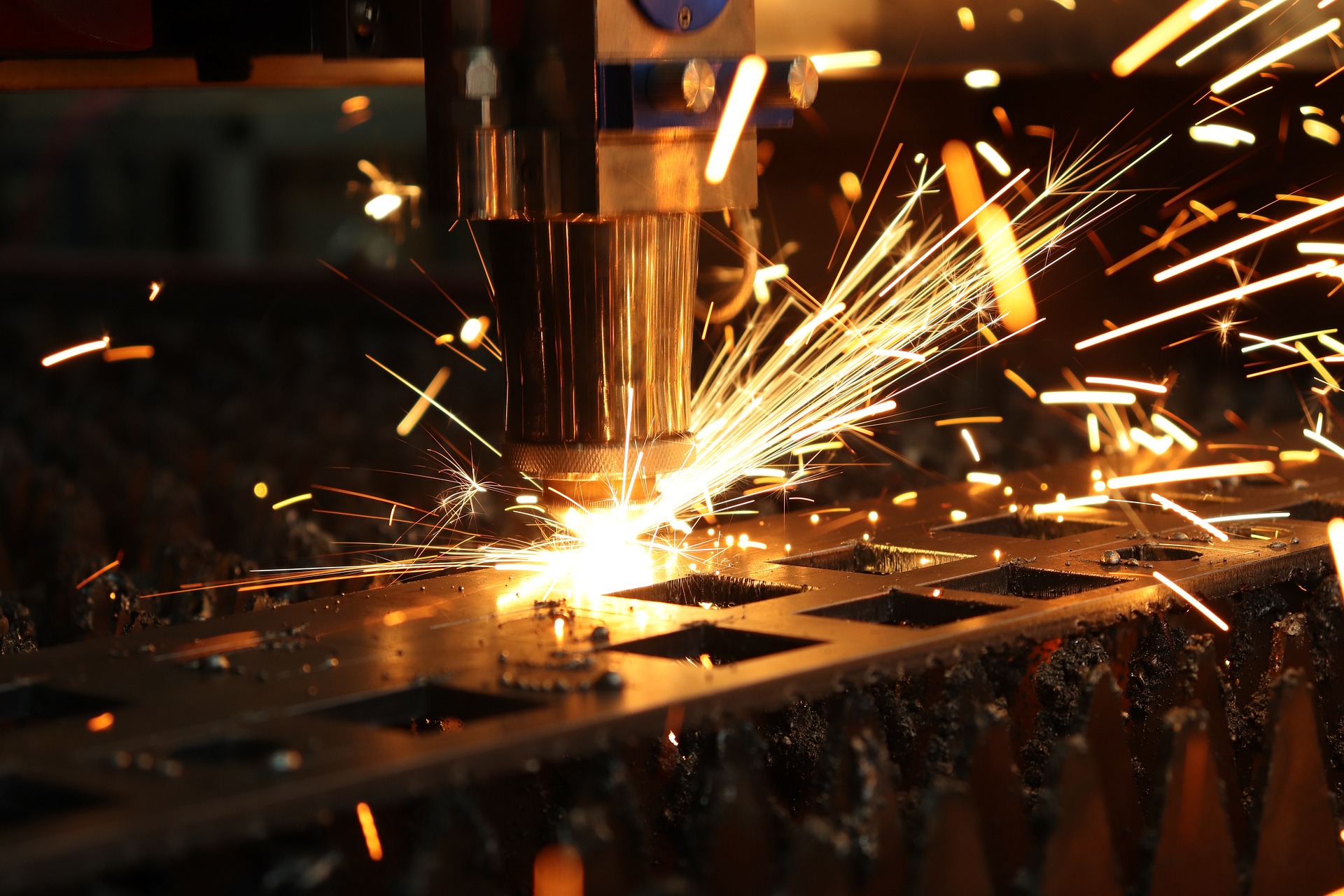

What is Fiber Laser Cutting & Why It's Superior in 2025–2026

Fiber laser cutting uses a focused beam of light from optical fibers to precisely cut metals. Compared to CO2 lasers or plasma:

- Higher accuracy (±0.1mm tolerances standard)

- Cleaner edges (minimal burr, no post-processing needed often)

- Faster speeds (up to 3–5x on thin sheets)

- Better for reflective metals like aluminum, copper, brass

- Lower operating costs (energy-efficient, longer lifespan)

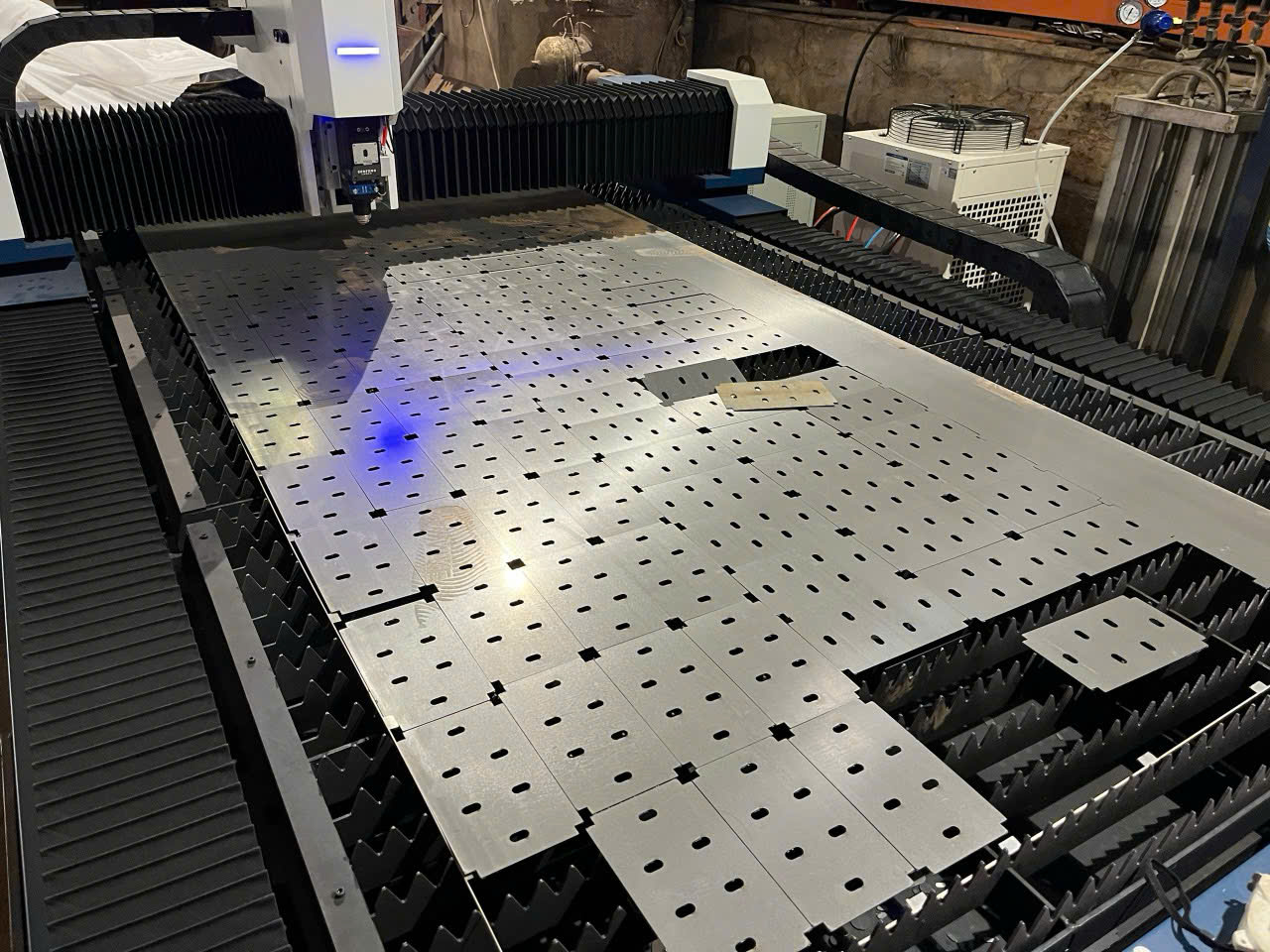

We use state-of-the-art fiber lasers (up to 40mm thickness capability) for thin to thick industrial metals.

Why International Clients Choose ATT MACHINE for Laser Cutting

- Extreme Precision: ±0.1mm tolerances, perfect fit for aerospace, medical, automotive parts.

- Speed & Cost Savings: High-speed cutting + advanced nesting software reduces material waste by 10–20% and shortens lead times.

- Full One-Stop Service: From laser cutting → CNC bending → machining → laser welding → powder coating. No need to coordinate multiple vendors.

- Global Accessibility: Optimized logistics from Vietnam to USA, EU, Australia—duty-free options, reliable shipping, English support.

- Proven Track Record: Trusted by global brands; ISO-compliant processes.

"ATT MACHINE delivered our stainless steel enclosures with perfect bends and zero defects—faster than our previous suppliers in China." – Procurement Manager, European Electronics Firm

Materials We Laser Cut – Thickness & Applications

| Material | Max Thickness | Common Applications | Why ATT MACHINE Excels |

|---|---|---|---|

| Stainless Steel | Up to 20mm | Medical devices, food processing, marine | Clean cuts, no discoloration |

| Aluminum | Up to 15mm | Aerospace, automotive, electronics | Handles reflective surfaces perfectly |

| Carbon Steel | Up to 25mm | Structural, heavy machinery, construction | High speed on thick plates |

| Brass & Copper | Up to 10mm | Electrical, decorative, heat exchangers | Minimal oxidation, precise details |

Other materials: Mild steel, galvanized steel, titanium (inquire for exotics).

Our Integrated Manufacturing Process

- Laser Cutting → High-precision flat patterns.

- CNC Bending → Salvagnini & press brakes for complex 3D forms with ±0.5° angle accuracy.

- CNC Machining → Threads, pockets, milling for finished features.

- Laser Welding → Clean, low-distortion joins.

- Powder Coating / Finishing → Durable, corrosion-resistant finishes.

How to Get Your Parts – Simple 4 Step Process

- Upload Drawings: Send CAD files (.DXF, .DWG, .STEP, .IGES) or even PDF/sketches via our portal.

- Instant DFM Review: Engineers check manufacturability, suggest optimizations (free).

- Production & Quality Control: Laser cut, bend, weld, inspect (100% visual + CMM checks).

- Global Shipping: Pack securely, trackable delivery + customs support.

Frequently Asked Questions

Q: Why choose ATT MACHINE instead of a local "laser cutting near me" shop? A: Local shops may be faster for small runs, but we offer superior fiber tech, full secondary services, competitive OEM pricing, and export experience—ideal for medium to high-volume or complex international projects.

Q: What file formats do you accept?

A: .DXF, .DWG, .STEP, .IGES primary. We convert PDFs, sketches, or 3D models if needed.

Q: Can you handle prototypes and high-volume?

A: Yes—from 1 piece rapid prototype to 10,000+ production runs.

Q: Where are you located and how fast is shipping?

A: Ho Chi Minh City, Vietnam. Air/express 3–7 days to most countries; sea freight for bulk.

Q: Do you provide certifications?

A: Yes—material certs, inspection reports, RoHS, REACH on request.

Ready for Precision Parts That Exceed Expectations?

Contact ATT MACHINE today for a free instant quote and DFM feedback.

Address: An Thanh Tech Co., Ltd., Ho Chi Minh City, Vietnam

Phone/WhatsApp: +84 942 127 028

Email: cokhi.anthanhtech@gmail.com

Upload Drawings & Quote: attmachine.com/quote

From prototype to production—let's build it right.